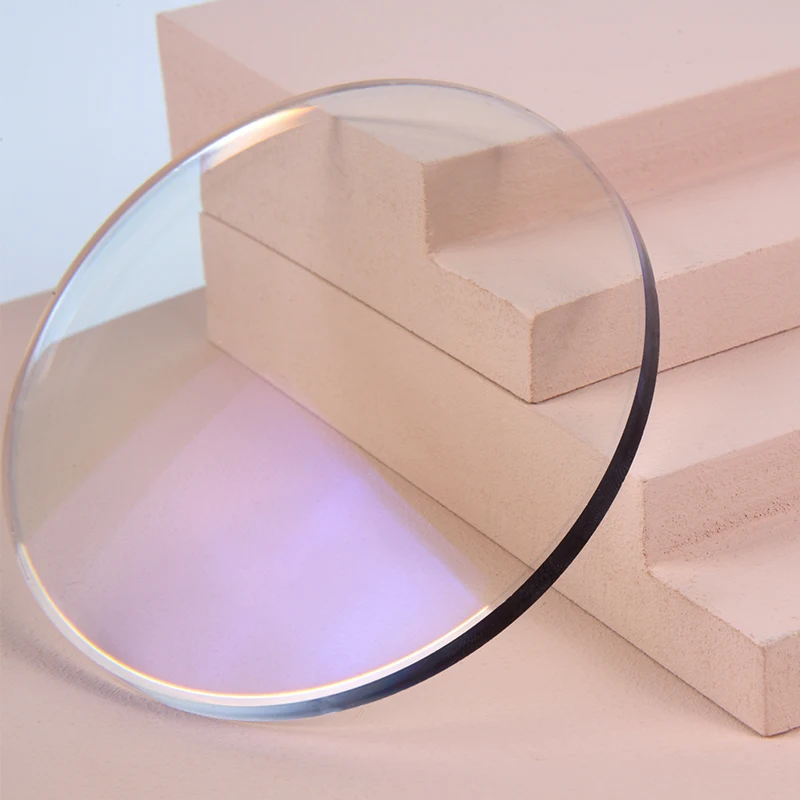

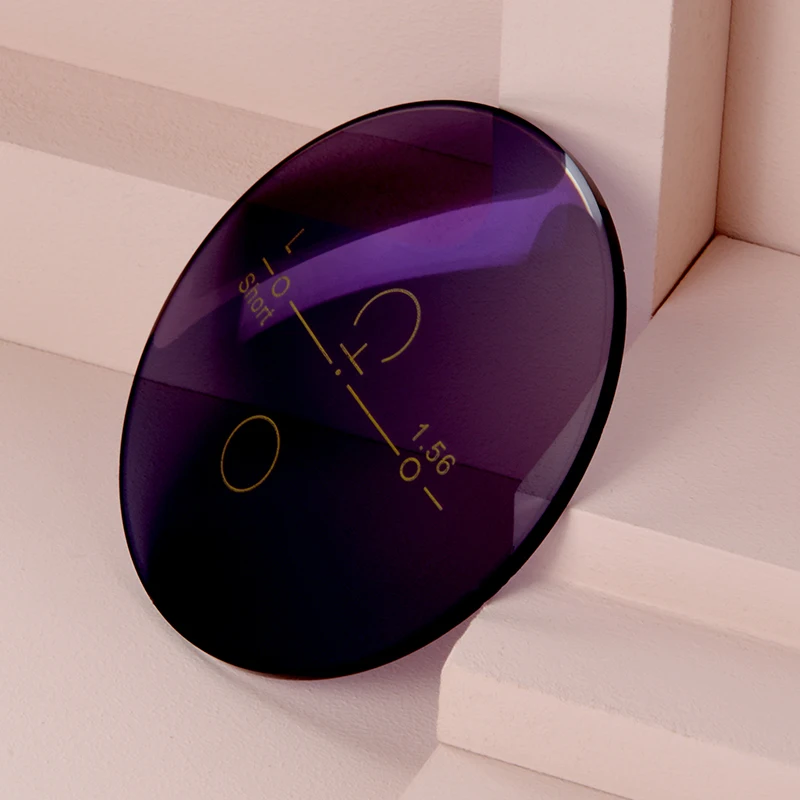

Introducing, the best choice customer product for your eyes- the Photon’s 1.59 Polycarbonate Optical Lenses Eyewear Glasses. Made of high-quality materials, these lenses offer unparalleled protection and comfort for your eyes, all in a fashionable design that is sure to turn heads wherever you go.

The first thing you will notice about Photon lenses is their clarity. These lenses are made of polycarbonate material, making them extremely durable and long-lasting. You won't have to worry about scratches or cracks affecting your vision when you are wearing Photon lenses. This makes them perfect for people who are always on the go and need a reliable pair of glasses that can keep up with their active lifestyle.

In addition to their durability, Photon lenses are also incredibly lightweight. This means that you can wear them all day without feeling any discomfort or strain on your eyes. Whether you're wearing them to work, school, or out on the town, you can rest assured that your eyes are always in good hands with Photon lenses.

Another great thing about Photon lenses is that they are available in a wide range of fashionable designs. Whether you prefer classic and understated or bold and eye-catching, there is a Photon lens that will suit your style. You can choose from a variety of colors and patterns to find the perfect pair of glasses that will complement your unique personality and fashion sense.

But perhaps the best thing about Photon lenses is that they are an affordable option compared to other high-end lenses on the market. You won't have to sacrifice quality for cost when you choose to invest in Photon lenses. You can enjoy all the benefits of premium eyewear without breaking the bank

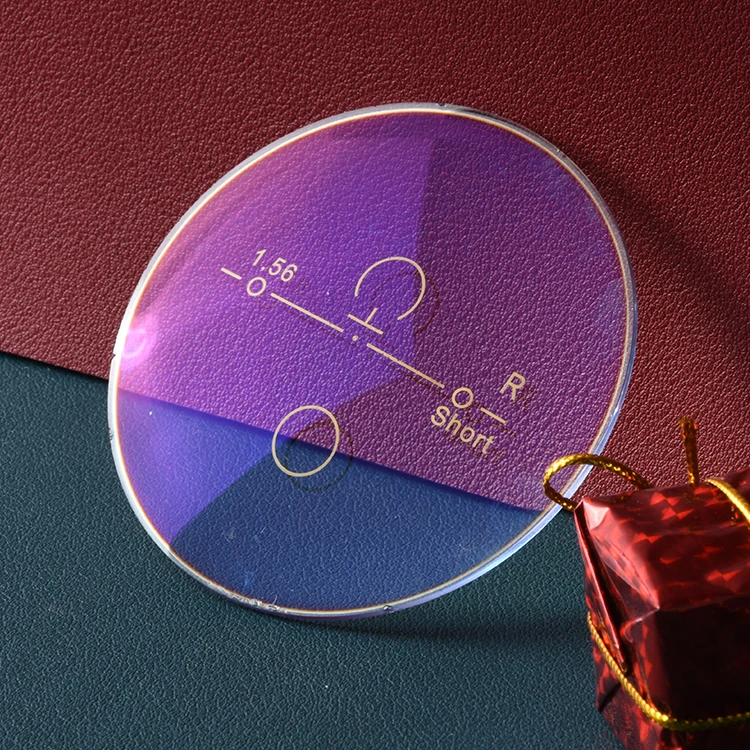

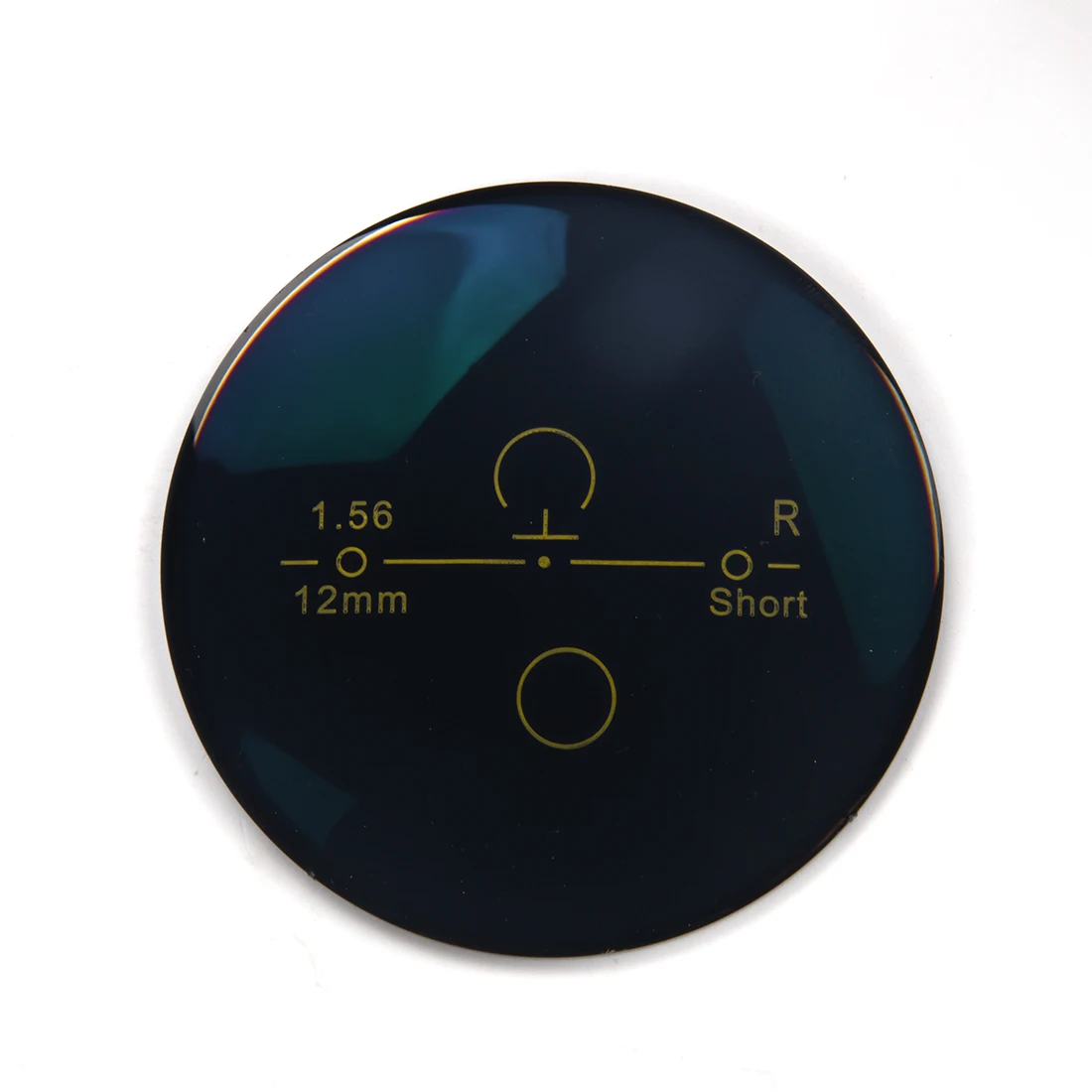

1.59 PC Blue Cut HMC Optical Lens |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

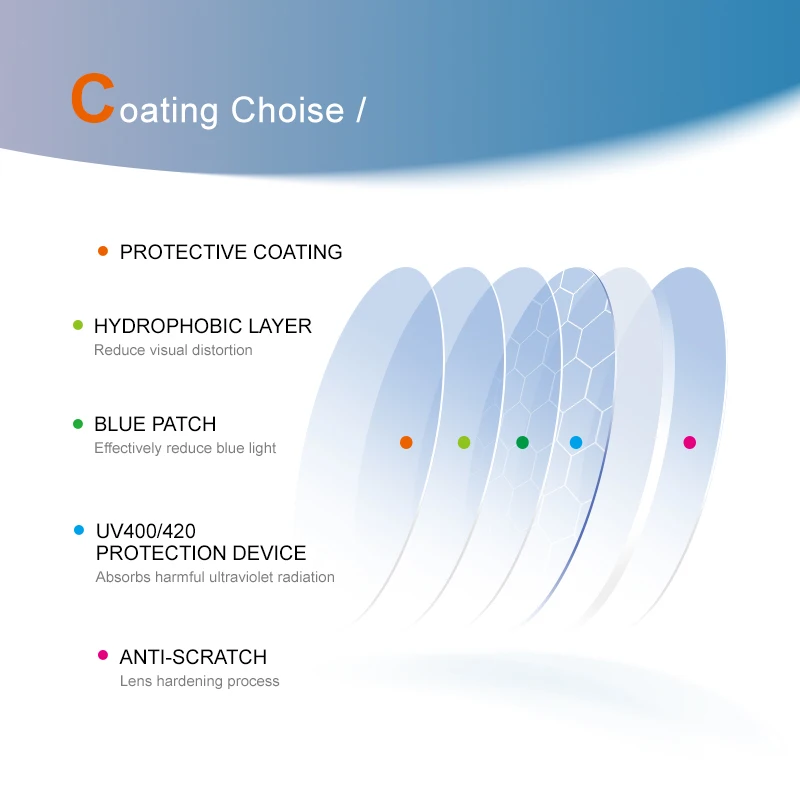

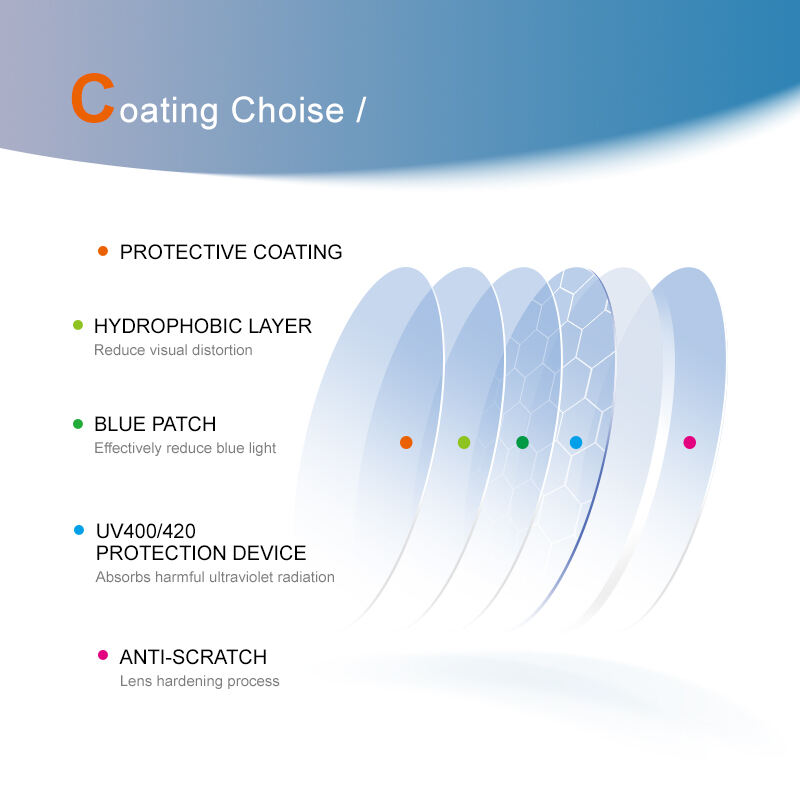

Hard and AR coating for both lens surface, suitable for people who spend a lot working with computer, mobile phone, laptop

|

|

1. Impact Resistant

Polycarbonate material was originally made for uses on canopies covering fighter planes and then made its way into space on astronaut visors and space shuttle windshields. Today it is readily available to the public. It impact resistance makes the material extremely suitable for sports, industrial safety goggles, and children's eyewear

2. Scratching Resistant

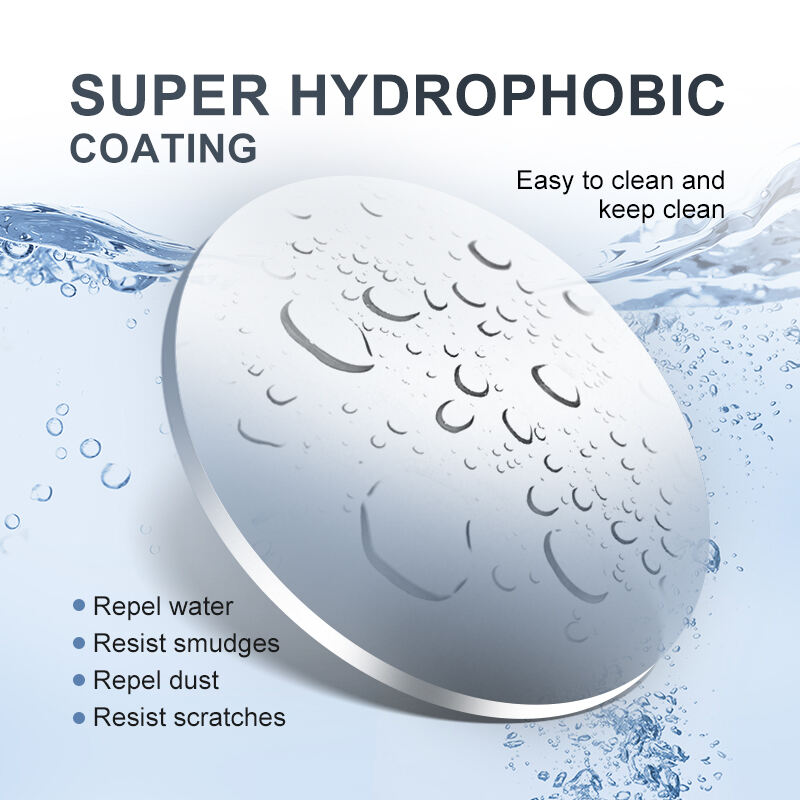

The reason for polycarbonate lenses' impact resistance is because of its "softness". Softer materials will flex instead of fragment when met with great force. However, the property allows lenses to be scratched easily. Therefore, every single one of our polycarbonate lenses is multi-coated with hard coating that forms a protective layer around the lenses allowing the lenses to be free from scratches while retaining its impact resistant qualities

a. upgraded coating technology, to provide outstanding optical features.

b. High quality material, to guarantee stable and premium quality.

c. Quality control throughout all the processes.

d. Comfortable and superior vision experience

What are our advantages

Thin & Light

A. Thinner lenses for lighter and more attractive glasses

B. Lightweight to free the nose bridge from burden

C. Ideal options for all prescription demands

Safe & Strong

A. Tough and impact resistant, ideal for eyes safety

B. Good tensile strength for fashionable rimless frames

Premium Optical Performance

A. High ABBE value and minimum stress strain

B. Outstanding durability for longterm usage

C. Ideal for various lens applications and precise progressive design

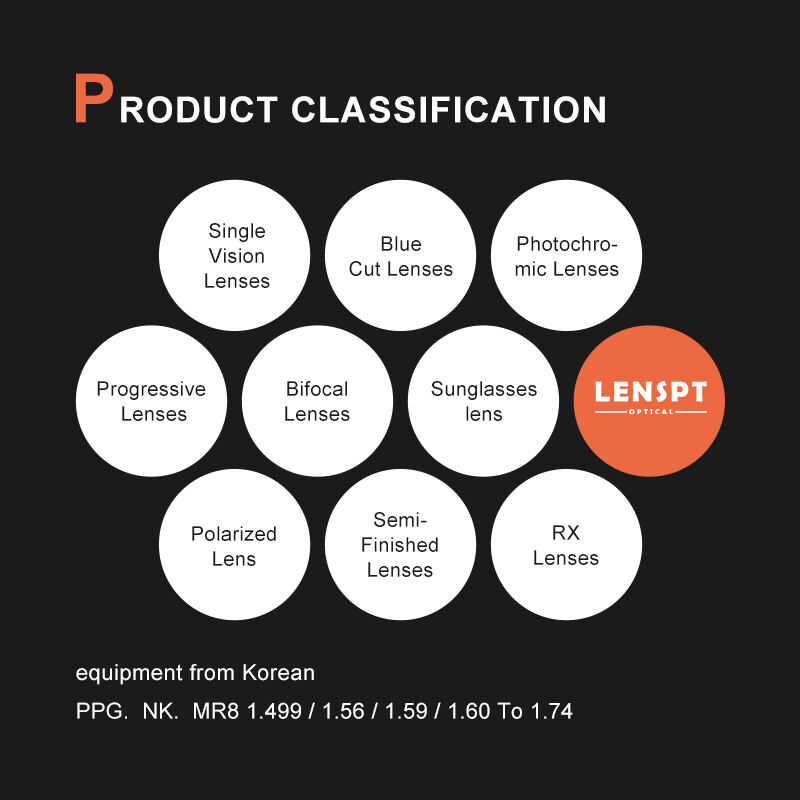

Index: 1.499, 1.56,1.60, 1.67, 1.74, 1.59 PC Polycarbonate

1. Single Vision Lenses

2. Bifocal/Multifocal lenses

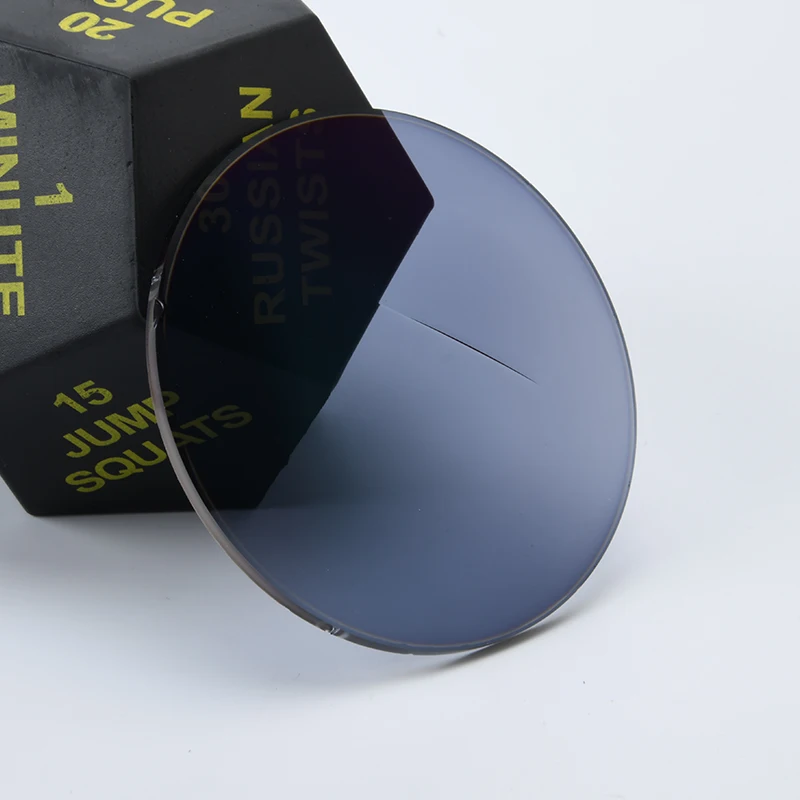

3. Photochromic Lenses

4. Blue Cut Lenses

5. Photochromic Blue Cut Lenses

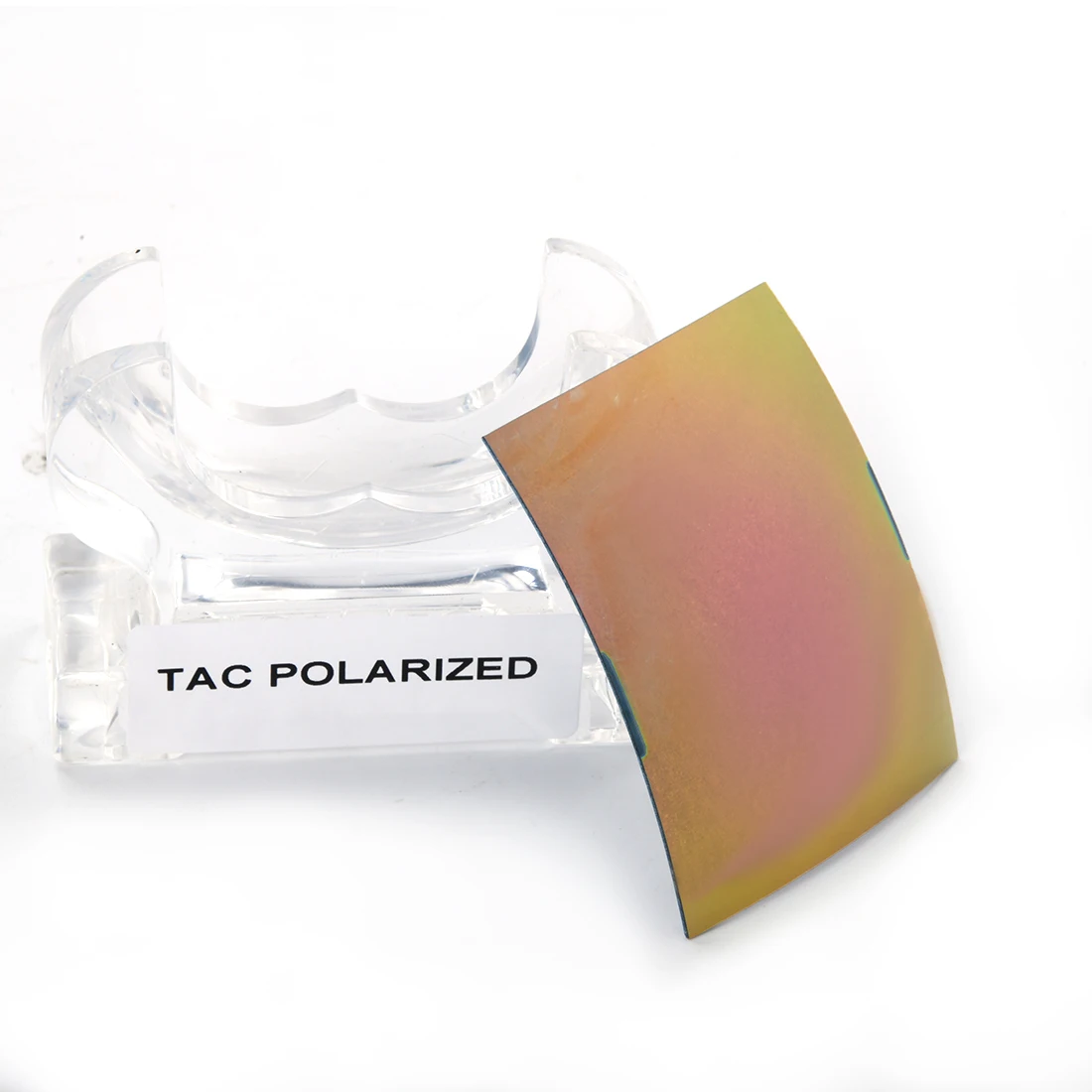

6. Sunglasses/Polarized lenses

7. Rx lenses for single vision, bifocal, multifocal

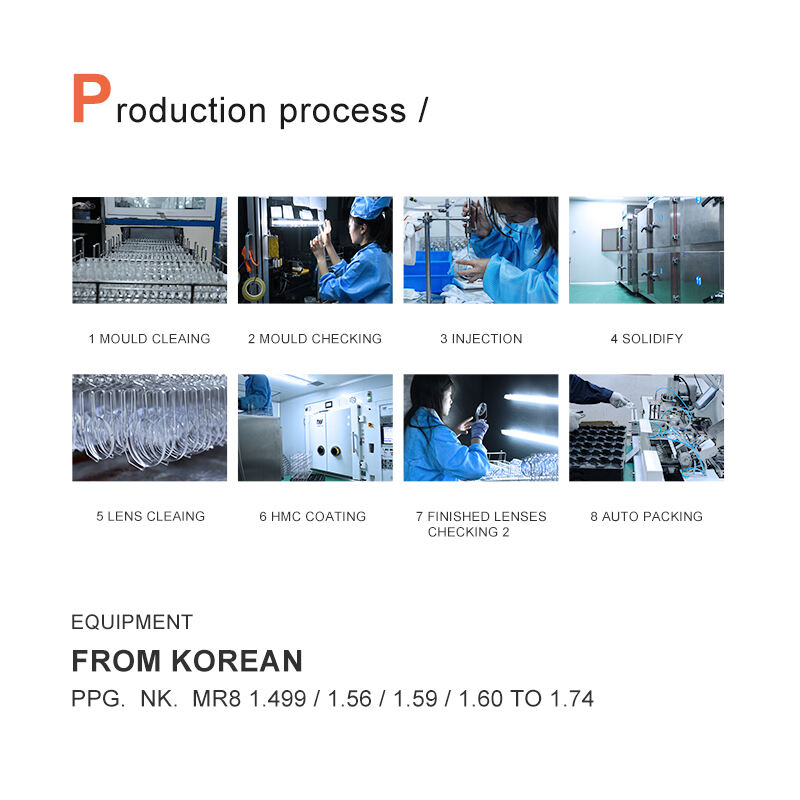

Q1: How about your optical lens production ability per dayA1: About 30'000 pairs/day

Q2: When will I get the reply from seller

A2: Within 24 hours due to the time difference. We will reply you as soon as possible

Q3: Could you provide free samples for customers checking the quality before they place the order

A3: Yes, of course. For those customers who are really interested in our products, if the quantity is reasonable, we would be very glad to provide our samples after get the detailed instructions from the customer

Q4: What is the term of payment

A4: 30% deposit in advance, 70% balanced paid before shipment

Q5: What's the delivery Time

A5: For your first test order, we will try to deliver after 15 days. Normally, the production time should be about 15 days for an order less than 1,0000 pairs. The exactly deliver time depends on your items & quantity

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

TH

TH

TR

TR